The compilation of many parts has come together to finally go on the ride. I've spent the past couple months putting together a,

"stage 2," kit for much less than Turner is asking. I subsituted the 24# injectors for 21.5. Stock s50 is 17#. I felt like 24 was just to high with stock cams and bottom end. My setup consists of:

Eurosport Cold Air Intake for 3.5" HFM w/ ITG Cone Style Filter (BFC used)

3.5" Euro M3 HFM (Bosch Part # 806 ebay.de)

21.5# Injectors (cleaned)

Bimmerworld Silicone 3.5">3.0" Intake Boot (New)

TMS OBD I Chip for listed mods (4131-3009)

In addition to the intake, injectors and chip, I also decided now would be a good time to put on the new valve cover, replace the valve cover gasket and do the spark plugs.

First things first I cleaned up the Eurosport CAI kit I got off BFC for $250. I felt it was pretty good deal considering it's about $400. The ITG filter was well taken care of and not disintegrating like a neglected one. Those alone are a bill. The heat shield was practically new and the CF tube cleaned up nicely as well. Overall I was happy with the purchase, as well as, build and craftsmanship of the

Eurosport products. Up next,

Twin Screw!

I used the "No-Toil," oil cleaner which worked like a charm. As you can see the filter was pretty nasty, but the oil released all the dirt. After the filter was clean I sprayed it down with some No-Toil Oil to keep it in good condition. I followed the instructions and saturated the thing. Maybe a little bit too much, but I just dabbed off the excess with a clean paper towel.

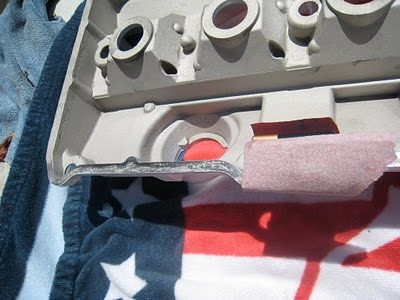

After that was done I prepped the valve cover to go on the car. The powder coating had crept onto the lower edge of the mating surface during the plating making a little raised edge. Since I was doing all this to fix an oil leak, I wanted to make sure the mating surface was flat and clean.

I took a little sanding block (9V battery :D) and some 180 to the mating surface. The coating is thicker and electro plated or something so nothing chipped off while I was sanding it like maybe a painted surface would. Durability was one of my main goals of getting the cover powder coated vs. painting it.

I also cleaned up the nasty baffle cover with some denatured alcohol. I clean everything with that. It's safe on plastics and breaks down oil pretty easily. For awhile I was just using Purple Power on everything but it ruined a few metal pieces and ate some plastic. So it's a little too harsh for "everything."

And here is the gangster cover one more time before it goes on the engine. I blew the cover clean with compressed air and, yes, that is a Lynard Skynard beach towel.

I started on the passenger side of the engine bay and worked my way over. I'm not going to go into much of the DIY of the VCG and plug replacement as it is covered pretty well in these Pelican tutorials.

I took the decretive "M Power," covers off to reveal the coil packs. I could've replaced these as well, but the wallet is only so full. One of the things that the Pelican article doesn't mention is that some s50 motors came with only one ground strap. After reading the DIY and noticing I only had one ground strap I consulted the forum. It looks like a couple other people verified that their s50 motors only had one ground. There was a marking on the coil pack where the ground was mated and no other marks on any other coil packs so I don't think it was a case of the PO losing it.

I guess I could have replaced the plugs with the cover still on, but I removed them next. After much a debate on plugs, coppers won my vote and are only about $2. I decided to run copper NGK BKR6E. OE search resulted in the 4 prong Bosch platinums which I haven't heard many good things about. It sounded like the track guys ran coppers and the, "I have to buy everything expensive because I have a BMW and buying expensive things makes me feel like I've spent my money on the right thing just because it's expensive," guys bought iridiums.

Conclusion was that a copper element preformed at a more consistent temperature and provided the same if not better performance than more expensive metals. The only possible down side is the higher interval change. The interval for changing them is around 15-20k miles, but honestly I would change any plugs at a minimum of 20k miles even if they were rated to last longer just because I'm that way, and at $2 a piece, you can.

Here's a pic of the old plugs. BKR6EK. I'm not a plug analist, but there was some old on the ends. The tips weren't fouled but the threads were oily. Hopefully it is just oil coming in from the valve cover gasket leaking. It definitely doesn't look like anything is running lean, which is good.

After the plugs were torqued down to 18ftlbs, I applied some high-temp RTV gasket sealer to the areas suggested.

I then laid the VCG down.

Here is my addition to the Pelican valve cover gasket DIY.

Make absolutely sure that the little tabs on the back of the gasket on the semi-circles are mounted on the side of the head and not folded under. The gaskets come shrink wrapped and bent up, and it's easy to just put the gasket down without noticing those little tabs. I did this, got everything done, started it up, drove it around and started to smell my oil burning oil worse than before. There was even a little smoke coming in from the vents. I took a look behind the head and noticed a splatter of oil. I looked at the old gasket, put two and two together, opened it back up and noticed both tabs on the semi-circles were folded down and under preventing a seal. Fixed it up and it sealed fine. I was able to reuse the gasket.

Next up, Injectors. All nice and cleaned up by

Osidetigerfics, ready to go in! I don't suggest just replacing the o-rings and pintle caps of some old injectors unless it's a budget build. Injectors get clogged after 15-20 years of use and it's a great performance gain just to clean your stock ones.

There isn't much to know about injectors if you've replaced them on a BMW before, but here is another write-up on Pelican.

I removed the clips and connectors when I moved the harness out of the way for the VCG install. I didn't want to get fuel everywhere so I didn't remove the fuel rail. Also the last time I removed some hose clamps which had found a nice 15 year home on a rubber fuel hose, it resulted in a fuel leak when trying to clamp the old hose back down. I wasn't going to replace any fuel hoses today so I was able to pop it out enough to swap in the injectors one by one.

Also Pelican says the injectors can come free from the manifold or fuel rail, but it's best just to keep them clipped on the fuel rail and pull them from the manifold. Mine actually didn't put up much of a fight and were easier to remove than those from e30s. Only thing is the pintle caps got totally destroyed as I pulled the injectors out. I didn't even notice if I cracked them or where they went, but one was definitely mia.

Ok....

Valve Cover, check

Injectors, check

Intake....

Alright, so I totally underestimated the intake. I figured, it's an intake. This will take about 5 seconds. Weelllllll, there isn't much room in there and a lot of time was spent mocking things up and getting it, "just right." I'm going to continue the

intake installation with Bimmerworld boot in a separate post.

Here is the finished installation of the intake and valve cover. I can't get the valve cover to photograph correctly without blowing out, but I think it looks the business. Now I just have to keep it clean.

After the intake and everything was buttoned up, the last thing I had to do was swap out the stock chip for the Turner chip in the DME. Pelican has also covered this in a DIY. Most chip suppliers will send you instructions unless you pick one up used of course.

The DME is located under the windshield on the passenger side of the engine bay. I removed it and took it inside. Remove the tabs on the back of housing, popped out the old chip with the white "H" covering and installed the new one in the correct direction.

I put the DME back in it's little home, connected the battery and fired it up. It took a few trys to get the fuel through the injectors. I had pulled the fuel pump relay prior to drain as much fuel as possible. Once it started up I noticed a much smoother idle. I took it around the block and on to the freeway and Man, it was quite a difference! You always here that from people, but seriously it's like a different car now. I'm very happy with the outcome. Next stop is going to be the dyno to see what these mods are putting down!